Stampings & Extrusions

“Enhancing Efficiency and Precision in the Stampings & Extrusions Industry through Advanced Manufacturing Solutions”

- Home

- Industries

- Stampings & Extrusions

Brochure

Download our document to see specific data of the service and how we work.

Let’s Start Work

Together

Please feel free to contact us. We will get back to you within 1-2 business days. Or just call us now.

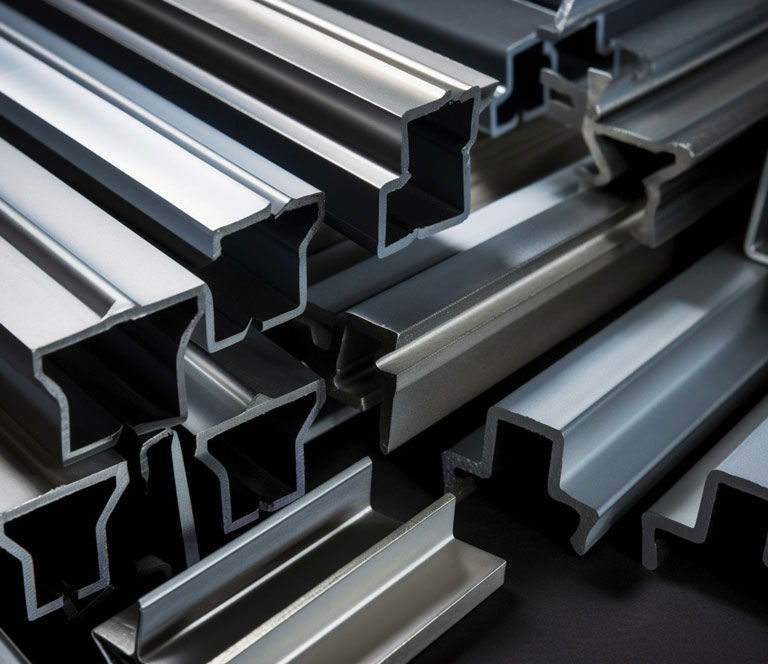

About Stampings & Extrusions

Precision stamping is a highly precise metal transformation process that utilizes specialized dies and presses to create specific components. At Jobwurx, we are experts in the design, development, and implementation of precision stamping techniques. Our focus on accuracy, repeatability, and tight tolerances enables us to deliver top-quality components that meet the rigorous demands of various industries. With our commitment to excellence, we ensure the production of complex geometries and consistent results, providing our clients with superior solutions.

Extrusion is a versatile manufacturing method employed to shape a wide range of materials, including metals, plastics, and rubber. By forcing these materials through a die of a specific shape, we can create continuous profiles, tubes, rods, and other customized shapes with exceptional precision and consistency. Jobwurx specializes in extrusion across multiple materials, catering to the unique requirements of diverse industries. Our expertise in this field enables us to provide tailored solutions that meet the highest standards of quality and performance.

Experience the reliability and excellence of Jobwurx’s precision stamping and extrusion capabilities. Our advanced manufacturing processes ensure accuracy, repeatability, and consistency in the production of components. Contact us today to explore how our tailored solutions can elevate your industry operations and deliver the desired outcomes.

Products Offered

Under the category of Dies & Moulds, our product range includes:

Stamped Parts: These are metal components produced through the stamping process, where a press machine applies force to shape and cut metal sheets into specific forms, such as brackets, clips, or connectors.

Extruded Profiles: Extrusions involve pushing or pulling a material, typically metal or plastic, through a die to create continuous shapes or profiles. Examples include aluminum extrusions used in construction, window frames, or automotive trim.

Sheet Metal Components: Sheet metal is processed and formed into various components, such as panels, covers, brackets, or enclosures, through cutting, bending, and shaping operations.

Stamped Gaskets and Seals: Gaskets and seals used in various industries, including automotive, aerospace, and manufacturing, can be produced through stamping processes to ensure proper sealing and containment.

Extruded Tubes and Pipes: Extruded tubes and pipes are created by pushing or pulling material through a die to form hollow cylindrical shapes. They find applications in industries like plumbing, construction, and automotive.

Extruded Rubber Profiles: Extruded rubber profiles are produced through the extrusion process and used in applications such as weatherstripping, seals, gaskets, or protective trims.

Stamped Electrical Contacts: Electrical contacts used in switches, connectors, or electrical devices can be manufactured through stamping processes to ensure precise and reliable electrical connections.

Extruded Plastic Profiles: Extruded plastic profiles are created by extruding molten plastic through a die to form continuous shapes, such as channels, tubes, or frames, used in various industries including construction, furniture, or automotive.

Stamped Fasteners and Clips: Fasteners like screws, bolts, or clips can be produced through stamping processes, providing efficient and reliable joining solutions for different applications.

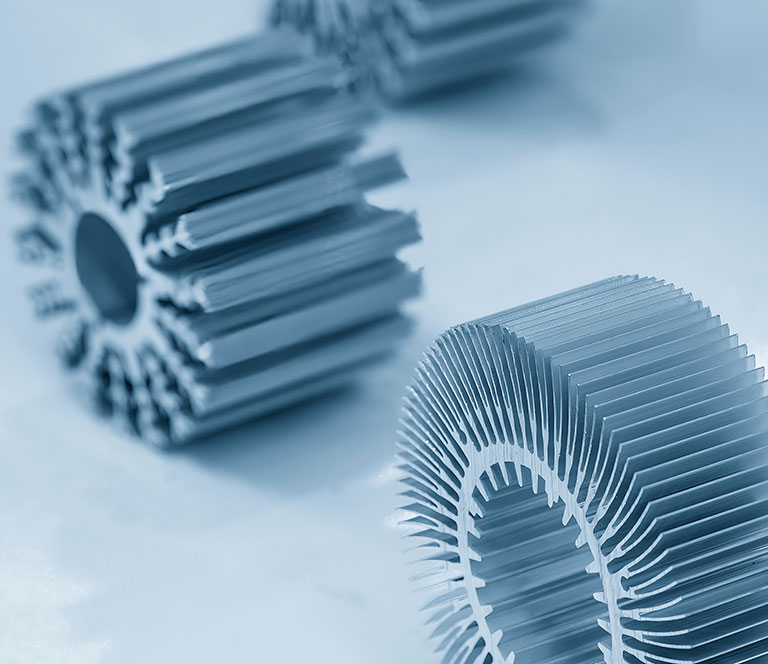

Extruded Heat Sinks: Heat sinks used for thermal management in electronic devices can be manufactured through extrusion processes, allowing efficient heat dissipation.