Castings and Forgings

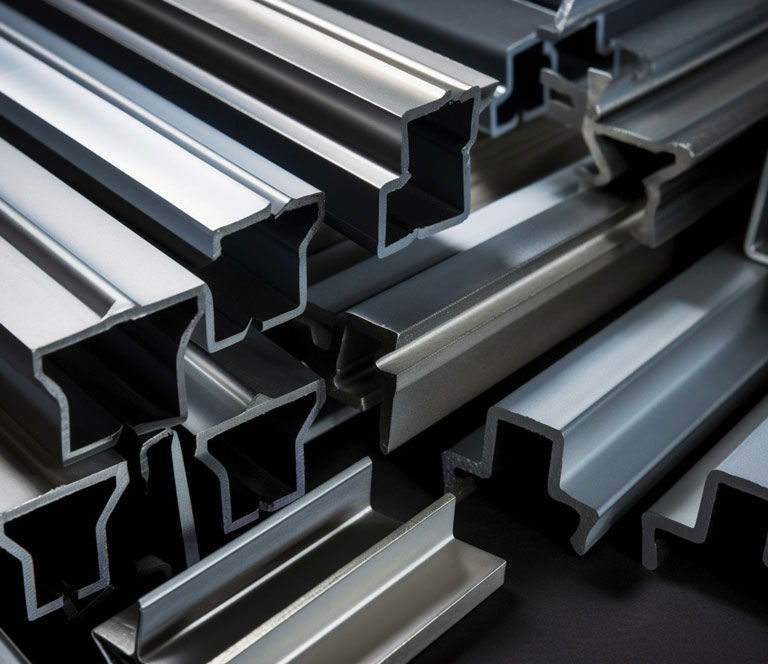

“Enhancing Efficiency and Precision in the Stampings & Extrusions Industry through Advanced Manufacturing Solutions”

- Home

- Industries

- Castings and Forgings

Brochure

Download our document to see specific data of the service and how we work.

Let’s Start Work

Together

Please feel free to contact us. We will get back to you within 1-2 business days. Or just call us now.

About Castings and Forgings

In today’s rapidly evolving industrial landscape, Jobwurx stands out as a prominent precision engineering company, specializing in CNC machining, VMC, and other advanced techniques. With a strong commitment to innovation and a rich history, Jobwurx has earned a trusted reputation as an expert partner in the aerospace, robotics, automotive, and industrial sectors.

This introduction aims to provide an in-depth overview of Jobwurx’s capabilities in precision machining and its role in the manufacturing of high-quality metal components. The company’s proficiency in working with various casting methods and forging techniques is highlighted, showcasing how Jobwurx contributes to the advancement of key industries through its cutting-edge machining capabilities.

Precision machining involves the precise shaping of metal components, adhering to tight tolerances and specific design requirements. Jobwurx excels in this field, utilizing advanced technologies, highly skilled personnel, and state-of-the-art equipment to ensure exceptional accuracy, surface finish, and dimensional precision.

Jobwurx harnesses the power of computer-controlled systems, such as Computer Numerical Control (CNC) and Vertical Machining Center (VMC), to achieve remarkable precision and efficiency. CNC machining enables automated and repeatable processes, while VMC machining offers enhanced versatility and speed, especially for complex components.

With its unwavering commitment to excellence and expertise in precision machining, Jobwurx is poised to meet the increasing demands of industries seeking top-quality metal components. Contact us today to explore how Jobwurx’s cutting-edge solutions can contribute to your success.

Products Offered

In the realm of Casting and Forgings, we cater to a wide range of industrial needs as follows:

Cast Iron Components: Known for their strength and durability, cast iron components find applications in engine blocks, pipes, valves, manhole covers, and heavy machinery parts. They provide reliable solutions for industries requiring robust equipment.

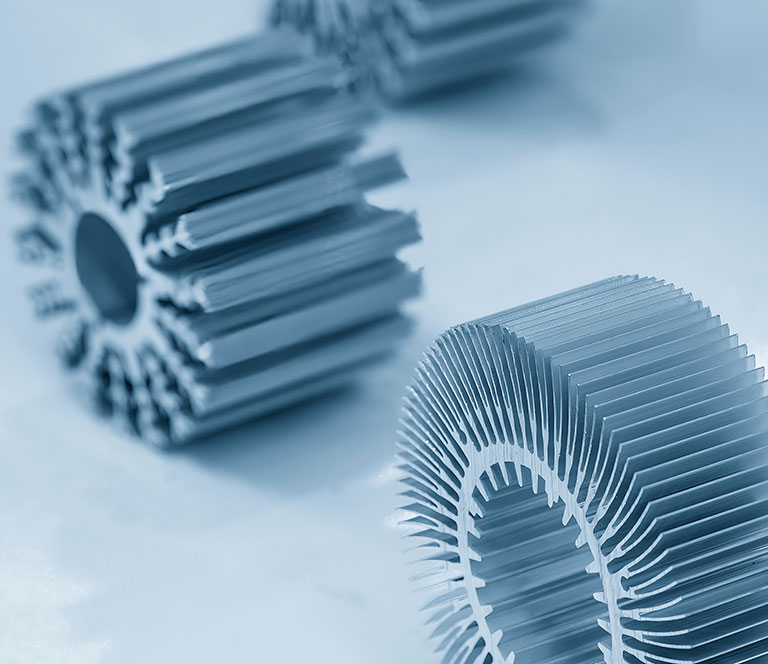

Aluminum Castings: With a combination of lightweight properties and exceptional strength, aluminum castings serve industries like automotive, aerospace, and decorative pieces. They are used in engine parts, automotive components, aerospace parts, and intricate decorative elements.

Steel Castings: Renowned for their strength, versatility, and mechanical properties, steel castings are utilized in construction, automotive, and oil and gas industries. Gears, shafts, pumps, and structural parts benefit from the reliability provided by steel castings.

Brass and Bronze Castings: Valued for their corrosion resistance and aesthetic appeal, brass and bronze castings are applied in plumbing fixtures, marine hardware, decorative elements, and musical instruments. They offer a blend of functionality and visual appeal.

Investment Castings: Investment casting, also known as lost-wax casting, produces highly detailed and complex parts for industries like aerospace, jewelry, and specialized industrial parts. It provides intricate and precise solutions for intricate designs.

Forged Steel Components: Forging shapes metal through heat and pressure to create strong and durable parts. Crankshafts, gears, axles, and heavy machinery parts benefit from the excellent mechanical properties and reliability of forged steel components.

Open Die Forging: Open die forging, also known as free forging, shapes the workpiece between two flat dies without enclosing it fully. This process is used to create large and complex components like shafts, bars, and blocks. It offers flexibility in shaping various materials, enhancing grain structure and mechanical properties.

Closed Die Forging: Closed die forging, also called impression die forging, shapes the workpiece between dies that mirror the final component’s shape. The material is fully enclosed, ensuring precise shaping. Closed die forging produces intricate and dimensionally accurate components with excellent strength and integrity. Industries such as automotive, aerospace, and oil and gas commonly use this technique for critical parts like gears and crankshafts.

Hot Forging: Hot forging is performed at elevated temperatures, enhancing the workpiece’s ductility and facilitating better material flow and shaping. This process is ideal for materials with high strength that are challenging to shape at room temperature. Hot forging is widely utilized in automotive parts, machinery components, and tools, ensuring precise shaping and superior mechanical properties.

Drop Forging: Drop forging utilizes a heavy, vertically moving hammer or press to deform the material between dies. This technique efficiently shapes the workpiece, producing strong and reliable components with optimized grain structure and mechanical properties. Drop forging is prevalent in the manufacturing of automotive and aerospace parts, hand tools, and hardware fittings.