Industrial Automation and Robotics

“Advancing Industries with Cutting-Edge Automation and Robotics Solutions”

- Home

- Industries

- Industrial Automation & Robotics

Brochure

Download our document to see specific data of the service and how we work.

Let’s Start Work

Together

Please feel free to contact us. We will get back to you within 1-2 business days. Or just call us now.

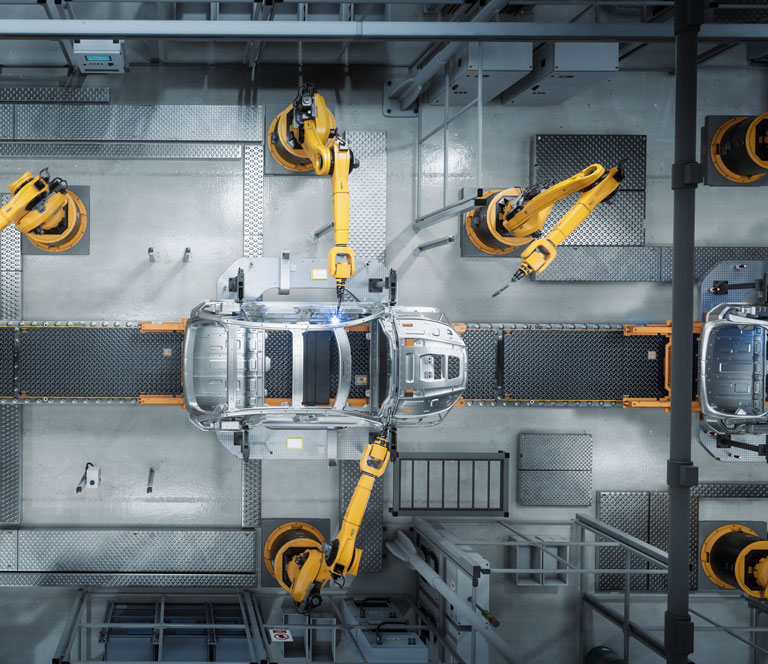

About Industrial Automation and Robotics

Jobwurx offers a comprehensive range of industrial automation solutions tailored to meet the diverse needs of industries. Our team of skilled engineers collaborates closely with clients to design, develop, and implement customized automation solutions that enhance production processes and drive efficiency. From streamlined control systems to sophisticated manufacturing lines integrating robotics and artificial intelligence, Jobwurx delivers cutting-edge industrial automation solutions.

Our extensive robot portfolio encompasses articulated robots, SCARA robots, collaborative robots, and gantry robots, enabling us to cater to a wide array of applications. Whether it’s welding, painting, material handling, or assembly, Jobwurx provides optimized solutions to automate these processes efficiently.

With Jobwurx as your automation partner, you can unlock innovation and achieve manufacturing excellence. Our industry expertise combined with advanced automation technologies empowers your operations, elevating productivity and improving overall performance.

Products Offered

Here are some commonly CNC machined components used in automation and robotics:

Robot Frames and Chassis: CNC machining is employed to manufacture frames and chassis for robots. These components provide structural support and house the various mechanical and electrical systems of the robot.

Motor Mounts: CNC machining is utilized to produce motor mounts that securely hold the motors in place within robotic systems. These mounts ensure precise alignment and reliable operation of the motors.

Gears and Gearboxes: CNC machining is used to manufacture gears and gearboxes for robots and automation systems. These components are crucial for transmitting motion and torque within the system.

Actuators and Linear Guides: CNC machining is employed to produce actuators and linear guides used in robotic systems. These components facilitate precise and controlled movement of robot arms, grippers, and other mechanical parts.

Sensor Housings and Mounts: CNC machining is utilized to manufacture housings and mounts for sensors used in automation and robotics. These components provide protection and proper positioning of sensors for accurate data acquisition.

Control Panels and Enclosures: CNC machining is used to produce control panels and enclosures for housing electronic control systems in automation and robotics. These components provide a secure and organized environment for the control electronics.

Jigs and Fixtures: CNC machining is employed to manufacture jigs and fixtures used in the assembly and testing of robotic systems. These components ensure precise positioning and alignment during the manufacturing process.

End Effectors and Grippers: CNC machining is utilized to produce end effectors and grippers for robots. These components enable robots to interact with objects, perform tasks, and manipulate the environment.

Connectors and Connective Components: CNC machining is used to manufacture connectors, brackets, and other connective components used in automation and robotics. These components enable the integration and assembly of various parts within the system.

Slides and Rails: CNC machining is employed to produce slides and rails used in robotic systems. These components facilitate smooth and precise linear motion of robot arms and other moving parts.